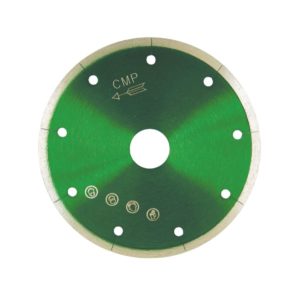

Bricklaying Tools & Cutting Melbourne

CMP Stone in Hallam are a stonemason tools supplier in Melbourne that specialise in Bricklaying Tools & Cutting Melbourne.

We also specialise in tools for:

- Monumental Stone Masonry

- Stone Masonry Tools & Equipment

- Bricklaying Tools & Equipment

- Marble Cutting Tools & Equipment

- Sculpting Tools & Equipment

- Landscaping Tools & Equipment

- Tile Cutting & Tiling Tools & Equipment

- Dry Wall Masonry Tools & Equipment

Bricklaying is an important step in the construction of any building, whether residential or commercial. But a lot of us don't really understand what bricklaying is. Bricklaying is the skilful execution of this task. Bricklayers use a wide variety of bricklaying tools and equipment to build and repair structures like pathways, walls, foundations, etc., making them a popular construction profession. Even though it's not complicated and can be grasped quickly, being a skilled and knowledgeable bricklayer takes a lot of time and effort invested over many years. The standard tools of a bricklayer's trade are masonry bricks and cinder blocks made of concrete. However, as technology has progressed, a wider variety of building materials has been available, and bricklayers must adapt to these changes.

Bricklayers follow plans and specifications to lay bricks, concrete blocks, stone, and other similar materials to build or repair walls, arches, chimneys, and fireplaces. One such field of employment is working with firebrick in commercial and industrial heating and combustion equipment. As a pulp mill worker, you may also be exposed to acid brick and tile.

You would use these supplies and your expert bricklaying talents to build and fix brick walls, arches, and other architectural elements.

But if you believe a bricklayer's only job is to place brick after brick, you'd be wrong. As with any occupation, there is more to being a bricklayer than meets the eye. Different abilities are required for each step of a single bricklaying process.

CNC TOOLS

8+ Products

GRINDING & SHAPING

20+ Products

CONSUMABLES

11+ Products

What does a Bricklayer do?

Measures the Area

A bricklayer's first step is to measure and mark the area that will be laid with bricks. He estimates the quantity of everything from bricks to mortar that will be required. The bricklaying process can then begin when the bricklayer has selected the best bricklaying tools and equipment for the job.

Chooses A Pattern

The next step is to settle on a design. Greater intricate designs can be created by a bricklayer with more training and expertise.

Laying the Bricks

After the space has been carefully measured and the desired pattern has been decided upon, the bricklayer can begin laying the bricks. It's a difficult, time-consuming talent that pays off in the long run. Visual appeal is just as important as structural integrity when it comes to the bricks-mortar bond, which should be very strong and constant from top to bottom and side to side. The mortar used by bricklayers must be of the right viscosity to ensure a strong bond and of the right moisture content to prevent drying out and becoming too thick to work with.

Final Touches

At the project's completion, the bricklayer adds the finishing touch by smoothing the mortar with the trowel's tip. The extra mortar on the bricks is also removed during this operation. Copper tubing, one of the most useful tools in bricklaying, is used to put the finishing touches on the job, giving the brick joints a professional appearance.

What Tools do Bricklayers Use?

Numerous brick mason tools, such as brick trowels, sledgehammers, steel tape measure, shovels, and combi drills, will be used on a regular basis. Each component serves a unique function and may or may not be necessary for your current endeavour.

There are four main types of tools and equipment used in the bricklaying trade:

- Tools that are held in one's hand, such as spades, hammers, and bolsters.

- Machinery, such as cement and mortar mixers and power drills.

- Equipment for determining distances, such as tape measures and laser levels.

- Carrying heavy objects like the bosun's chairs.

Tools for setting out, cutting bricks, laying bricks, and joining bricks are all subsets of this larger category. Bricklayers sometimes employ tools such as blow torches, welding machines, line pins, rawhide mallets, and pneumatic chisels. An additional circuit tracer or multimeter, among other electricians' instruments, may be required for any electrical job. Stainless steel brick mason tools and cutting-edge power devices are becoming increasingly available from a wide range of manufacturers.

Trowels types

Bricklayers cannot do their work without trowels. Masons use them to spread mortar or plaster when laying brickwork. The blade of this compact hand tool is flat and can be anywhere from five to twelve inches in length. Depending on what you're working on, you may use the following:

Bricklayers' smallest trowel is the pointing trowel, which they employ for detailed work. It is typically utilized for pointing work and any other tiny chores that may be required. Typically, a blade's length will range from 12 to 15 centimetres or 5 to 6 inches.

Tools for finishing walls smoothly are called edging trowels. These trowels are similar to finishing trowels but have rounded edges, allowing you to create seamless transitions at the corners of your walls. The edging trowel is similar to the finishing trowel in that it helps you get the precise finishes on the edges of your work area, whether you are working with mortar, concrete or plaster.

Brick trowels, which feature a long, pointed blade for spreading mortar - The brick trowel is larger than the pointing trowel yet similar in shape. They're what get to work picking up and distributing that mortar. The length of their blades ranges from 25 to 30 inches, with the average being 10.

The flooring trowel has a flat face that is squared off at one end and pointed at the other, making it ideal for working in tight quarters and around corners. Having an even floor is crucial, and a flooring trowel is a necessary tool for the job. Because of its shape, it is able to fit snugly into corners, allowing you to level any uneven area.

Smoothing trowels are used to finish off a job using plaster, cement, or concrete. The finishing trowel's big, flat face helps you to smooth, level or texture the surface coat of mortar, plaster or concrete. It's really necessary for getting professional-grade results in the end products you create. If you're a bricklayer or plasterer who cares about your craft, you need a finishing trowel.

Many other trowel types are also available, such as screed trowels, plastering trowels, joint trowels, notched trowels, bucket trowels, and many more. You can extend the life of your instruments by cleaning and oiling them after each use. Their handles are often made of wood or plastic and can easily shatter if submerged in water.

You might want to get a trowel set so that you always have the tools you need. Avoid buying the largest or cheapest options available. Too large of a trowel might be cumbersome to deal with.

What exactly do line pins do?

As a reference, bricklayers place these tools in the brick course and secure them between stones. As they make progress, they take them out and promote them to the next level.

Use line blocks instead of line pins for shoring up corners. Since you can't buy the tools that block masons use, most of them have to create them themselves.

What is Gauge Rod for?

You will never be able to estimate by eye, no matter how much experience you have. Taking precise measurements is essential in this field. Here, the gauge rod will prove to be invaluable.

For determining courses and verifying the gauge in bricklaying, use this handy device. Commonly used models are composed of aluminium and include markings of every brick's thickness. It takes the form of a long, straight stick and can stretch for several meters.

You'll also need a spirit level, a tingle, and other bricklaying tools; these are not optional for any professional bricklayer. In order to ensure that the wall is straight, a spirit level is utilized.

It has two tiny panes or vials, and each one holds liquid and a tiny air bubble. When the bubble of air in the vial aligns with the markings, you know that the wall is perfectly horizontal or vertical. Although these are simple to operate, they do necessitate a steady hand and keen eyes.

Find out much as you can about the most common bricklaying tools and how they are used. Especially if you're just starting out in the industry, it's best to visit a brick-and-mortar business instead of making purchases online.

Purchase a reasonable Measuring Tape

Bricklaying requires precise measurements, thus, a measuring tape is a must for setting out the work area. Pick a steel version that is at least five meters in length. Look for convenient functions like an automatic locking mechanism, a retractable design, and an end hook that can be adjusted to fit your belt.

You might want to get a folding ruler. This unit of measurement is available in a variety of forms and dimensions. Excellent scale models are typically fabricated from fibreglass, which can be cleaned easily.

Invest in a Metal Square

This sturdy steel instrument facilitates the verification of internal and external angles, the designing of square constructions, and the taking of measurements. Sizes range from small to large, and it's made to withstand the elements and corrosion.

What Are Bolsters?

Equipment for chopping bricks is where we'll be going next. You'll want to start by obtaining support. With this chisel and a hammer, masons can do quick masonry of chopping into chases or bricks. There is a wide selection of models to choose from.

The brick bolster is a cold chisel with a wide cutting blade, generally pounded with a lump hammer to split bricks.

In order to enhance the effectiveness of your hammer blows, you can use a brick bolster to focus the force of your blows in one specific spot. This makes it a great instrument for use during the demolition phase, when, for instance, bricks or tiles must be removed.

You can split stone, brick, and even metal with a bolster made of bricks. Make sure you have the brick marked where you want to cut it before using this tool. Then, centre the bolster over the drawn line, chisel down to within half an inch, and tap the bolster's head with a hammer. It's important to trim the surplus before making a clean cut.

The bolsters and handguards should be of sufficient weight and strength to withstand repeated cutting. See to ensuring that everything fits snugly together. It's possible that you'll also require additional, similar masonry tools, such as pointed chisels, fluted or plugging chisels, cold chisels, or electricians' chisels. The debris can be easily removed using a plugging chisel, while cold chisels are used to make holes in brick.

Cold Chisel

A cold chisel is a tool used to chip away mortar and remove old brickwork. It is a simple steel rod with a sharp, curved cutting end. To help dismantle preexisting structures before construction begins, this instrument is invaluable.

What are the functions of the brick hammer?

The brick hammer is standard equipment for each bricklayer's tool belt. It has a handle and a heavy head with two sides, and it's commonly referred to as a Stonemason's hammer. It can make clean breaks in brittle materials like stone, brick, and concrete. Its basic form and style have remained unchanged for generations.

Use extreme caution if handling a hammer. Strike it in the head rather than the side. You should shield your eyes using goggles.

What are the functions of the Claw Hammers?

Because of its versatility, this style of the hammer has become the industry standard. The average model weighs at least 16 ounces, making it difficult to hold. A bricklayer will use this to pry nails out of wood and other materials.

Every tradesperson needs a reliable claw hammer. To drive nails and pry them out. If you need to demolish a building or simply get rid of a few nails, this tool can be invaluable.

You can choose between a straight rip claw and a curved claw hammer, both of which serve different purposes. You may want to use a forged version because it will survive longer. Take care; claw hammers shouldn't be used on metal.

Lump Hammer

Bricks can be broken and cut using this heavy hammer, which normally weighs 1.2kg (42oz) and is used in conjunction with a brick bolster.

When starting a demolition project, a chunk hammer can be used to help knock down walls or other buildings.

Brick Hammer

When used for its intended function, the brick hammer makes quick work of smoothing and shaping bricks and another masonry. The "T"-shaped hammer has a chisel on one end and a blunt one. You can use the chisel side for chipping away at masonry and stone, while the other, blunt side, can be used for driving. Perfect for adjusting the size of bricks you already have.

Get a Solid Sledgehammer

A sledgehammer is the best tool for cutting or splitting bricks. When it comes to demolition work, this big equipment, which can weigh as much as 42 ounces, is your best bet.

Masons utilize this device for masonry, destruction, breaking masonry, hitting cold chisels, and freeing locked things. Always use protective eyewear. If not, flying particles could cause eye damage.

Buy a nice Steel Scraper

To clean up after yourself, use this jointing tool to scrape off any leftover mortar, paint, or dirt. It either has a wooden handle and a steel blade that is forged together, or it comprises a wood handle and a steel blade.

How Necessary is the Pointing Trowel?

Filling and shaping masonry joints requires a pointed trowel. Very similar in appearance to a bricklayer's trowel, this instrument consists just of a steel blade and a wooden grip.

Purchase a Laser Level

A laser level is not as complex as its name implies; it may be used by anyone. Whatever your needs, you may set it up on a tripod, mount it to the wall, or set it down on the floor. In order to facilitate efficient and precise designing, this device projects a laser line or point.

A laser level is a self-balancing device that projects a beam of light onto a surface after using an internal spirit level or pendulum level to ensure verticality. When the detector is in line with the laser, it will emit a beep to indicate this. With a range of up to 300 meters, laser levels are suitable for both small and large-scale bricklaying projects. Bricklayers will be able to accomplish high-quality work quickly and accurately with the help of the laser-level gadget, eliminating the need for the laborious use of a spirit-level bar.

In construction and other fields where precision is essential, laser levels have found widespread application. In addition to aligning decks and fences, homeowners and builders can also use these instruments to measure land elevations, set up chair rails, level floors and walls, and perform a variety of other tasks.

Obtain the required outcomes by purchasing a high-quality model. Determine which of the many available laser levels is most suited to your needs by doing some research. For tiling, a square laser level is ideal. Modern self-levelling models function well even in low-light settings, and multi-line pattern laser levels are flexible and simple to set up.

SDS Drill

If you're working on a substantial job, you should invest in a mains-powered, industrial-strength power drill. When doing operations such as drilling several holes in concrete or masonry, the motor of a conventional cordless drill might overheat and burn out if it is not powerful enough.

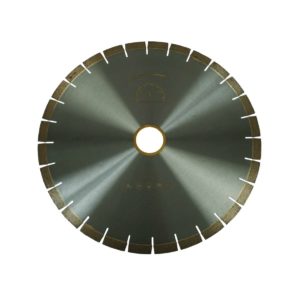

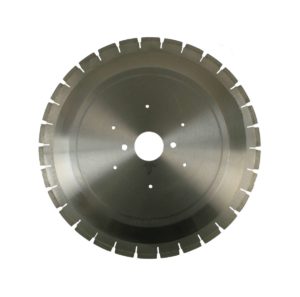

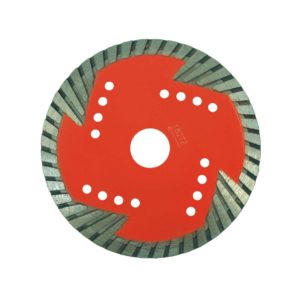

Pick a Perfect Masonry Saw

Stone, concrete, and bricks are just some of the many materials that may be cut with this equipment. Tungsten carbide, which is resistant to high temperatures, is used to make the long blade and massive teeth. The teeth on some variants are rounded.

There is a wide variety of masonry saws to choose from. You can get models with 27.5-inch blades. Compared to other brick mason equipment, this sort of saw carries greater dangers and can quickly lead to injuries. Therefore, you must maintain safe work conditions and wear proper equipment (PPE).

This gadget is not to be used on any kind of step stool or ladder. Keep it at arm's length or lower so you can easily manipulate it. Wear a face shield, hard hat, goggles and boots when handling a masonry saw.

String Line

A string line, also called a bricklayer's line, is a tool used to establish a straight line along which bricks can be laid.

String line is a time-tested method that has been used by bricklayers for generations to guarantee the straightness of their work.

Shovel

The modest shovel is sometimes disregarded as a necessary tool, yet this is not the case. The shovel's larger blade is perfect for scooping rubbish and providing approximate measurements.

You can pat things down or smooth them out with the blade's back. If demolition is required, it can also be used to pry plasterboard from walls. Sturdy and long-lasting; will serve you well for many years.

Digging Spade

The digging spade is an all-purpose implement that can be used to make deep cuts in the earth. If you need to dig a trench in preparation for constructing a wall or other structure, this is the tool for the job.

To make this step of the process as simple as possible, you should invest in a high-quality digging spade.

Rabbiting Shovel

Post holes and deep, narrow trenches are made for with the rabbiting shovel. Digging in tough soil is a breeze with the tiny blade.

Holes excavated using a rabbiting shovel are perfectly round and don't disturb the soil. Because of this, they can be used as grounding conduits for things like cables and pipelines.

Build Your Tool Kit

No matter how skilled or experienced he is, every block mason needs to invest in high-quality masonry tools and equipment. Having access to high-quality tools can help you save time and money. They'll last longer, too, so you won't have to keep replacing them every few months or years.

There is typically a hefty price tag attached to the best masonry equipment. But you may arm yourself with the fundamentals and expand from there. If you need a tool but don't have the money to buy a new one, look into purchasing a used one or trying to find an alternative that will do the job.

Brick Jointer

Brick jointers are hand tools used to make grooves in mortar joints right as they are set. An investment in a brick jointer is money well spent because it increases the durability and aesthetic appeal of the mortar. ... It's a general term for anything that can be used to mold the mortar between bricks.

These simple metal tools, known as jointers, are used to smooth out the joints in your mortar. The many jointer models each produce a unique look. The brick jointer is an essential piece of equipment for producing flawless brickwork and maintaining pleased clients.

Brick Hod

Bricks and mortar can be transported with the use of a brick hod. The use of brick hods helps hasten construction projects by transporting bricks to the worksite's designated locations. The brick hod is easier to move around than a wheelbarrow and can be lifted onto upper levels and scaffolding without difficulty.

To transport bricks or other building supplies, typically mortar, a brick hod is a triangular box with two additional handles. ... In the construction sector, hod hauling is a common form of manual labour. A hod-carrier, sometimes known as a hoddie, is an employee of a bricklaying crew who assists the bricklayers in carrying materials.

Long-Nosed Pliers

Pliers with long noses are useful for cutting and gripping. They are versatile and can be used to manipulate wire in many ways. The cutting edge is located close to the joints of the pliers, making them a useful "one-tool." Their eponymous long nose enables great handling. Because of their length, they may access tight spaces where cables or other items have been lodged and cannot be reached by hand. They allow for precise manipulation and may fit into small openings where fingers would otherwise be unable to.

Brick Tongs

Brick tongs are devices that allow one person to carry a large number of bricks or blocks at once. Using a cantilever movement, the brick tongs clamp down on bricks or blocks when the handle is lifted. Most brick tongs feature arms that can be adjusted to hold anywhere from 6 to 10 bricks, while other models may hold as many as 11 bricks. As the handle is raised, the clamping jaws of the brick tongs close and secure bricks or blocks in place by a cantilever movement. It's common for brick tongs to have extendable arms that can hold anywhere from 6 to 10 bricks, and there are even models that can hold 11 bricks.

If you need to move a number of bricks from one location to another, but don't want to bother with lifting each one individually, you can use brick tongs, a basic gadget that employs lever pressure to hold the bricks in place. This comes in very handy when you need to get bricks to out-of-the-way spots or when you are working at varying heights.

Builders Square

Right angles in brick and block work are marked with a builder's square. The builders square is a time-honoured device for ensuring precise, accurate results. Spirit levels are being used in newer constructions by some square builders to ensure precision.