Marble Cutting Tools & Equipment Melbourne

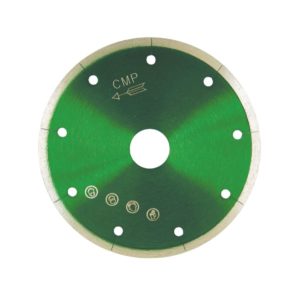

CMP Stone in Hallam are a stonemason tools supplier in Melbourne that specialise in Marble Cutting Tools & Equipment Melbourne.

We also specialise in tools for:

- Monumental Stone Masonry

- Stone Masonry Tools & Equipment

- Bricklaying Tools & Equipment

- Marble Cutting Tools & Equipment

- Sculpting Tools & Equipment

- Landscaping Tools & Equipment

- Tile Cutting & Tiling Tools & Equipment

- Dry Wall Masonry Tools & Equipment

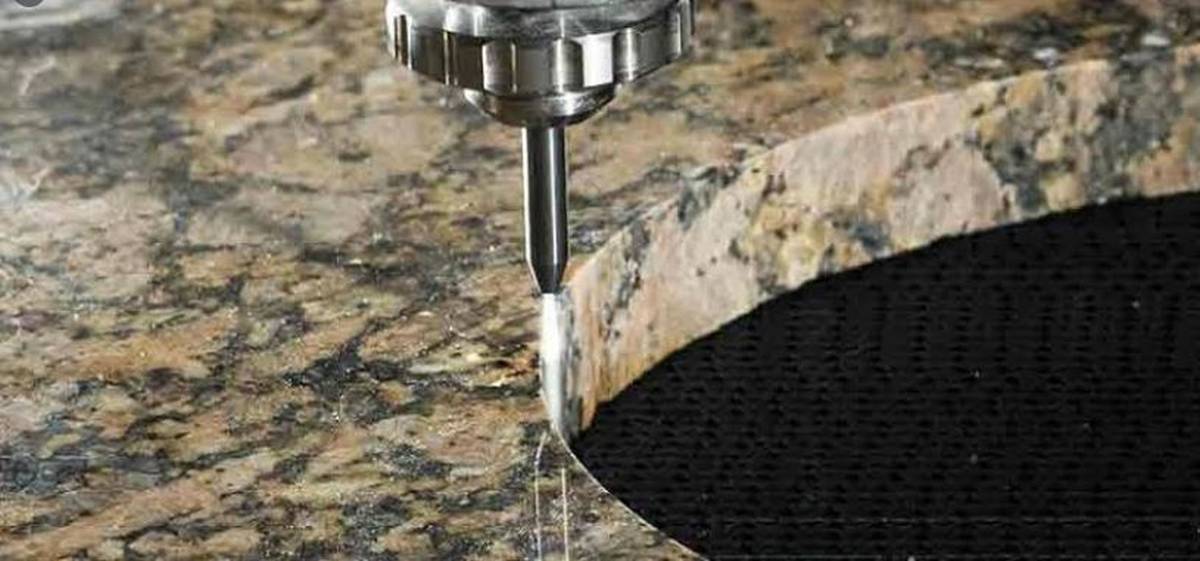

Artists of the past fashioned works of art out of marble by carving them with a hammer and chisel. Because of the time and effort involved, it's possible that today's consumers wouldn't be willing to wait three years for their marble countertops to be made by hand. Thankfully, that's no longer the case. Working as a Modern Marble Cutter typically involves using massive machinery.

To be a Marble Cutter, a machine is a trusted companion. In return for your tender attention, it expedites your work. Every shift, it is the Marble Cutter's responsibility to make sure that the machine is properly lubricated and that the water and oil levels are at the proper levels. You can avoid injury by cutting the stone instead of yourself with a freshly sharpened saw.

When everything is set up, you inspect the pattern you'll be cutting. Load the marble into your machine with a forklift, and then instruct the equipment to perform the necessary cuts based on your specifications. You let the machine do the actual labour, but you stay nearby in case it needs your assistance.

As soon as the cutting process is finished, you remove the object from the cutter and check that it conforms to the blueprint. You use hand tools to hone down any sharp edges, leaving a supple, rounded product.

Their work environment is noisy and dirty. Massive clouds of marble dust are kicked up with every cut, and the blades make a piercing shrieking sound. But you're safe and sound in your fashionable headgear, so it doesn't matter much to you.

CNC TOOLS

8+ Products

GRINDING & SHAPING

20+ Products

CONSUMABLES

11+ Products

Tasks of Marble Cutters

Tasks of Marble Cutters

- Measure the depths and widths of any cuts or carvings to make sure they match up with the design documents.

- Verify that a finished product or piece of work complies with standards by measuring its dimensions.

- To ensure a flawless finish, run your fingertips over the carvings with the intention of touching every part of the surface.

- Examine the final touches on finished products or work samples.

- Examine artifacts or graphic resources (such as a model, design, or blueprint) to figure out how to cut or carve anything.

- Examine plans and other documentation to establish steps in the process.

- Utilize the proper equipment to refine crude carving designs by shaping, trimming, or making minor adjustments.

- Eliminate any surplus from your workpieces.

- Create permanent markings on materials, workpieces, or goods by engraving drawings, writing, or other details.

- Carve designs or figures into stone in full or bas relief using your artistic talent and understanding of stone carving techniques to create carvings that match designers' plans.

- Produce permanent markings on materials, workpieces, or products by engraving drawings, text, or other markings.

- Prepare stone surfaces for carving by laying down designs or transferring dimensions from sketches or blueprints using scribes, chalk, and measuring instruments.

- Mark materials or finished products with guidelines or markings using a pattern or other reference.

- Prepare rough blocks of building or monumental stone for use in construction by cutting, shaping, and polishing them to to specifications.

- Preparing raw industrial materials for further processing or production via cutting.

- Create stonework by drilling holes, cutting or carving mouldings and grooves, and polishing to specifications.

- Create permanent markings on materials, workpieces, or goods by engraving drawings, writing, or other details.

- Make a hole in something, such as a piece of machinery or a substance.

- You'll need to choose the right chisels, pneumatic or surfacing tools, or sandblasting nozzles, and figure out the best order to employ them.

- Choose manufacturing machinery in accordance with product requirements.

- Create a preliminary sketch, then use mallets, chisels, or pneumatic tools to chip along the lines to create a design in stone.

- Create permanent markings on materials, workpieces, or goods by engraving drawings, writing, or other details.

- Use stencils as a guide and run nozzles over the stone, or chip along the lines to make designs or get the desired finish.

- Create permanent markings on materials, workpieces, or goods by engraving drawings, writing, or other details.

- Rub stones over the surface of sculptures to make them smooth.

- Material, work, or final goods can be polished to a shiny sheen.

- Modify the look of the stone by pounding it with bush hammers.

- Put abrasives into the sandblaster, connect the hoses, then open the valves to let the pressurized air out and turn on the jets.

- To load materials into manufacturing machinery.

- During the blasting process, you can alter the cut depth, design complexity, and roughness by adding or removing stencils.

- Take off any attachments, tools, or extras you find on a piece of machinery.

- Equip goods with adornments or add-ons.

- Construct crude clay or plaster replicas based on copied drawings.

- Mark materials or finished products with guidelines or markings using a pattern or other reference.

Marbe Cutting Tools

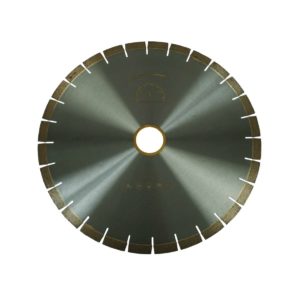

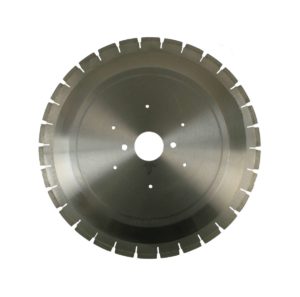

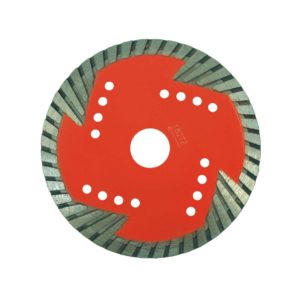

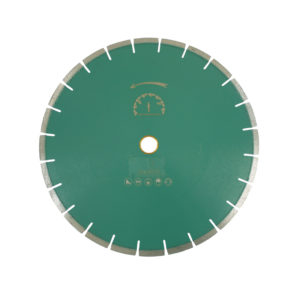

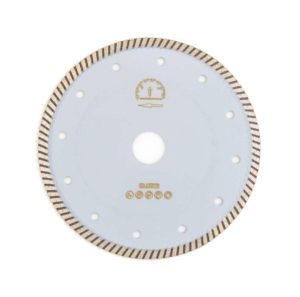

Marble cutters can range from being straightforward hand tools to intricate electric machines. A few examples of hand tools are nippers, cutter boards, beam score cutters, and glass cutters. Angle grinders and tile saws are examples of the more advanced power tools.

Marble cutters are handy appliances for slicing tiles into custom patterns. Marble cutters can range in complexity from simple hand tools to sophisticated motorized machinery. Tools like nippers, cutter boards, beam score cutters, and glass cutters are all considered hand tools. Tile saws and angle grinders are examples of sophisticated power tools.

Hand Tools

Nippers

When trimming the edges of stone tiles, even the simplest tile nippers come in handy. To accommodate a pipe or other impediment, nippers can be used to create a notch in the edge of a tile.

Cutter Boards

Many people believe that a marble cutting board is the cleanest option available. As a result of its hard and nonporous top surface, marble is notorious for dulling blades. It is impermeable, making it a desirable material for chopping boards.

Beam Score Cutters

To use the ceramic tile cutter, one scratches a line over the tile's surface with a hardened metal wheel, then presses down on the tile just below the line and on either side of the line on top. There is a wide range of snapping pressure, with some mass-produced devices able to generate over 750 kg of force.

A carriage carrying both the cutting wheel and the breaking jig rides along one or two beams to maintain the proper cutting angle and ensure a straight cut. The beam or beams could have a height adjustment to accommodate a range of tile thicknesses.

The base of the device may feature a set of adjustable fences that allow for both angled and square cuts, as well as fence stops that allow for consistent spacing between consecutive cuts.

The scoring wheel may be swapped out in a jiffy.

Glass Cutter

For safely breaking glass into two pieces, a glass cutter is used to form a shallow score on one surface. Glass is more likely to break in the direction of the score because it creates a fissure in the surface.

Power Tools

What Are The Benefits Of Using Marble Cutters?

Simple instructions are included with the marble cutters. Just connect the cord to an electrical outlet. This also helps saw blades last longer in use.

The dust is reduced by the marble cutters. They make it easier to make clean cuts with little effort. It's fine for anyone to use the marble cutters for their typical use. Inside the marble cutter is where the dirt and dust settle; this is where the cleaning supplies come in handy.

You can get the same high-quality results without the hefty price tag when you use these marble cutters. The market is stocked with a wide selection of marble cutters, each of which can be found in a varying price range according to its unique set of features. In the building industry, marble cutters are indispensable.

The time wasted during the cutting of marble is typically minimized by the experts.

Since a clean, precise cut reduces the amount of polishing that must be done on the final product, the marble cutter is a useful tool. With a high-powered machine gun and a sharp blade, the marble could be hacked through in no time. The marble cutter's cutting wheel is optimized to maximize productivity while producing a high-quality finished product. The marble cutters are sealed and equipped with a lock and toggle. In this way, even if the cutter falls into a body of water, its functionality will not be impaired. The cutting disc in the marble cutter is held in place by a spindle, making it simple to replace and clean.

What other materials the marble cutter could be used on?

Besides marble, the marble cutter can slice through paper, plastic, and even metal. Metal, marble, wood, concrete, and other materials fall into this category. The marble cutter's design allows for adequate manipulation, covers nearly all materials, and guarantees a smooth cut every time. The precision and speed of the marble cutters is impressive. Marble cutters have a number of moving parts and can have a metal or plastic housing for the motor. If you're having trouble settling on a cutter purchase, it's in your best interest to learn as much as possible about the various applications of cutters and which ones best meet your needs.

Angle Grinders

Grinder attachments for angle grinders are sometimes known as disc or side grinders. It's a portable electric tool for slicing, grinding, and buffing.

Power sources for angle grinders include electric motors, gasoline engines, and compressed air. When the abrasive disc or thinner cut-off disc on an angle grinder wears out, the motor rotates the head at an acute angle so that it can be swapped out. It is common for angle grinders to have a guard that can be adjusted as well as a side handle for use with two hands.

Tile Saws

Wet-cutting marble is simple using a regular circular saw and a diamond blade. Your best bet is to accomplish this task outside, where you can easily clean up with a quick spray from the garden hose.

Put the marble tile down on a 2-inch thick pad for support. A slab of dense, stiff foam. Use a marker to draw a cutting line on a long strip of tape.

Put a trickle of water on the leading edge of the diamond blade and hold the hose in place with your palm. To proceed with the cut, please use safety glasses. You won't believe how fast this low-tech approach can carve marble. If the edges are very rough, you may easily smooth them down with an orbital sander and progressively finer grits of sandpaper, from 40 to 400.