Concrete Cutting Tools Melbourne

CMP Stone in Hallam are a stonemason tools supplier in Melbourne that specialise in concrete cutting tools and blades in Melbourne. We also specialise in tools for:

- Monumental Stone Masonry

- Stone Masonry Tools & Equipment

- Bricklaying Tools & Equipment

- Marble Cutting Tools & Equipment

- Sculpting Tools & Equipment

- Landscaping Tools & Equipment

- Tile Cutting & Tiling Tools & Equipment

- Dry Wall Masonry Tools & Equipment

Skilled operators utilizing specific saws with diamond-impregnated blades undertake the concrete cutting process of controlled sawing, drilling, and removal of concrete. Concrete cutting today uses water instead of dust-generating jackhammers, resulting in a clean, aesthetically pleasing result. Wall sawing, core drilling, and slab or flat sawing are the three most prevalent types of concrete cutting.

Concrete removal and grinding will eventually be required, whether for repair work or renovations. You can break up the concrete using a saw or a drill during this time. Concrete cutting describes the actions involved.

When doing so, tangible age becomes an issue. When concrete gets old, it gets hard to see through.

This method calls for specialized saws and trained personnel. Because of the importance of accuracy in this task.

Because of this, the old methods are no longer practical. Noise, clutter, and sloppy work result from using jackhammers, chisels, hammers, and sheer power. However, with today's technology, concrete may be cut so precisely that it doesn't need any more polishing.

Several types of saws are used for this purpose. What you'll require is determined by the concrete's hardness. These days, saws with diamond-impregnated teeth are more often used for cutting concrete. The water is used to cool the blade, making the dust less of an issue. A different variety employs blowers or vacuums to remove the dirt.

Our Range of Concrete Cutting Tools & Blades

CNC TOOLS

8+ Products

GRINDING & SHAPING

20+ Products

CONSUMABLES

11+ Products

Types of Concrete Cutting Equipment

Electricity, an engine, hydraulics, or pneumatics can all power this concrete-cutting gear. While electrical tools are the most user-friendly, they aren't ideal for demanding tasks.

Cutting using an engine-powered saw will be cumbersome and precise. Saws powered by hydraulics or pneumatics, on the other hand, may be carried around easily and pose fewer dangers.

The concrete must be designated precisely where the incision will be made. If the desired cutting depth is less than four inches, a manually operated cutter is the way to go. For depths more than four inches, industrial machinery is recommended.

Whenever you're cutting concrete, make sure the workers' well-being is your top priority. In case you forgot, rebars and other embedded components are a normal part of concrete. Before beginning to cut the concrete, it is best to locate these embedded items.

Concrete dust is another issue that must be dealt with; as it is harmful to the lungs, the operator should always wear protective gear, including goggles and a face mask. It's a good thing that blowers and vacuums can keep things under control here.

Also, watch how much water you use. You need to make sure the water is drained properly because most concrete cutting equipment uses water to cool the blade and prevent dust. Electrocution is a real risk when water is present near any type of electrical device.

Cut-off machines — the industry standard

Cut-off machines, which are handheld saws used for slicing through concrete, asphalt, and metal, are the tools of choice for the majority of concrete-cutting projects. Cutting in construction typically involves the use of a composite resin abrasive wheel or a diamond blade. Cut-off machines, typically ranging in size from 12 to 14 inches, can be powered by a variety of sources, including two-stroke gas engines, hydraulic power units, air compressors, and electric motors.

Power sources can be either renewable or nonrenewable, depending on the requirements of the task at hand. Some workers prefer electric saws to other cut-off tools because they are more portable, produce less noise, and require less training. However, they lack the strength of more powerful alternatives and may take more time to accomplish the same task.

In confined spaces, an electric cutter is the tool of choice. It's not so much about performance in those circumstances as it is about what's required for the circumstance at hand.

However, the power-to-weight ratio of hydraulic saws is unparalleled. As most contractors already have a hydraulic power unit on hand, they're easy to operate, but they're also more expensive and less forgiving than, say, a pneumatic saw.

The pressure they create in the hydraulic system might make handling them challenging. A hydraulic line leak is also dangerous and costly.

Since air compressors are typically present on construction sites, pneumatic saws are also a useful tool. It's easy to use, and there aren't as many risks involved. If the blade becomes stuck, the air pressure can be released. No fluids will spill, either. Saws powered by compressed air are not only portable but also easy to keep in working order.

However, the cost of using a pneumatic saw can increase if you also need to buy a compressor and diesel fuel to run it.

Cutting machines that run on gas are the most common. These devices are convenient because of their portability and familiarity, but they need more upkeep than other instruments.

Weight versus performance is a concern in addition to energy needs and upkeep. A lighter saw is preferred by operators because it is more manageable, but this convenience comes at a cost. What the operator wants is entirely up to them. Lighter saws will cut shallower and require more passes, which could increase the cutting time. However, a heavier saw can cut more deeply and more quickly, but its weight can make it awkward to use for some people.

Time is money for some people. Some people avoid doing so to avoid exhausting the driver.

When operating a cut-off machine, it's important for operators to keep in mind a few key points. The final user is responsible for reading and complying with all instructions and safety precautions contained in the manual. All required PPE, as specified in the user handbook, should be available to the end user.

Diamond chainsaws fill a very specific niche.

In the same way as a regular chainsaw has a powerhead, guide bar, and chain, a diamond chainsaw has these same components, but instead of cutting wood, it cuts diamonds. To cut through wood, a diamond chainsaw uses diamond segments laser fused to the chain, as the name suggests. Similarly to a conventional circular diamond blade, the diamond segments grind away at the aggregate material, in this case concrete, brick, or stone. Thanks to the grinding motion, cutting is a very safe process that doesn't involve any kickback, unlike when using a wood chain.

There are a number of benefits that diamond chainsaws have over circular blade cut-off devices. More than twice as deep as a 14-inch circular blade, the chainsaw is made to dive headfirst into the material. Even the smallest ICS gas saw has a full 10-inch depth of cut, while other gas saw models have a complete 16-inch depth of cut.

The standard depth of cut for gas saws used on construction sites is 12 inches. It is possible to make a 25-inch cut using a hydraulic diamond chainsaw. A cut-off saw with a 14-inch circular blade can only cut to a depth of about five inches.

Diamond chainsaws, which use a guide bar with a long, narrow, flat surface, allow the user to achieve square corners by providing a deeper cut with no overcut. With a circular blade, that is simply not doable. Cutting deeper with no overcuts, diamond chainsaws can also be used to create apertures as small as 4 inches by 4 inches. Material can also be carved into unusual shapes with their help.

The most crucial factor in choosing a diamond chainsaw is whether or not you need to make cuts deeper than five inches. If you said "yes," then you should use a diamond chainsaw. Most people get their feet wet with a gas-powered two-cycle engine since they are inexpensive and easy to transport.

A diamond chainsaw with additional power and the ability to use guide bars for openings up to 25 inches is an option if you need to cut a lot of material.

Hydraulic and pneumatic diamond chainsaws have a greater power-to-weight ratio than their manual counterparts. Pneumatic or hydraulic saws will operate significantly better than manual saws when cutting hard concrete with steel reinforcement.

Silica dust control when cutting concrete

Dust management is an important consideration whenever concrete is being cut. The Occupational Safety and Health Administration published a final rule in 2016 on silica dust exposure, lowering the PEL for respirable crystalline silica in the workplace. The new eight-hour sampling cap is 50 micrograms per cubic meter of air. There was once a cap of 250 micrograms.

Engineering measures, such as water or ventilation, must be used by contractors while cutting concrete to reduce worker exposure to silica dust. In the event that exposure cannot be sufficiently reduced by engineering measures, personal protective equipment (PPE) such as respirators must be made available.

Wet cutting is advised for cutting concrete to reduce dust. Since the dust is bound by the water, less of it is released into the air during the cutting process. A dust collection system is an alternative.

When cutting concrete, it is important to employ dust control measures, not only because they are mandated by OSHA but also because they protect employees' health and safety. Choose the proper saw for the job, but don't forget to install a dust suppression system at the same time!

How to Cut Concrete

Cutting concrete might be a challenging task, but it doesn't have to be. Here are several simple methods for cutting strong concrete, whether you need to cut blocks, slabs, walls, or floors.

Easy ways to cut tough concrete

Most of us have mixed feelings towards concrete. When we require a long-lasting, industrial-strength, weatherproof surface, this is our favorite option. I despise having to fix, replace, or trim anything.

Cutting concrete can seem like an intimidating task, but it doesn't have to be. Choosing the appropriate resources is worth the bulk of the effort. You may use a concrete saw. The best tools and methods for completing typical concrete-cutting operations are outlined here, ranging in scale from tiny to monster-sized.

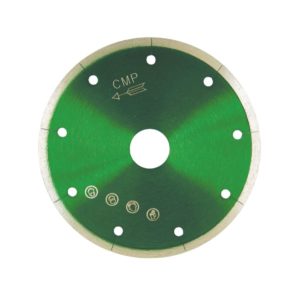

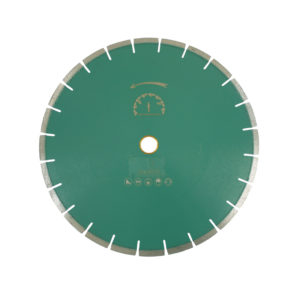

Concrete Cutting Tools: Diamond blades

While corundum blades are less expensive upfront, they are more expensive than diamond-tipped blades in the long run. Many places that rent out the diamond circular saw blades measure the blade's circumference before and after use and base their pricing on the 1/1,000th of an inch of the blade that was actually cut.

A cold chisel and sledgehammer can be used to produce rough cuts, but a circular saw fitted with the appropriate blade is the superior option.

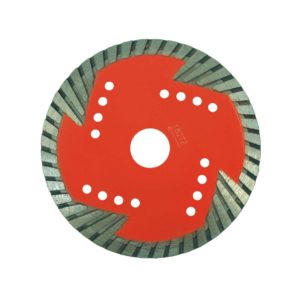

Types of Blades

Inexpensive (less than $5 for a 7-in. blade), easily accessible, and able to saw through concrete, stucco, and asphalt, abrasive corundum masonry blades are a great investment. They're cheap, but they're not very efficient, and they can only cut depths of 1/4 in. to 1/2 in. Every pass, and thus every cut, takes time. In addition, they quickly deteriorate. A blade's diameter will decrease from 7 inches at the start of a cut to 6-1/2 inches by the end. After a couple of feet of cutting in a straight line, you'll need to raise or lower the blade of your saw to expose additional material. Corundum cutting blades get so heated they can shine, stink, and produce clouds of fine dust. When you simply need to make a few small, shallow cuts, they are a cost-effective option.

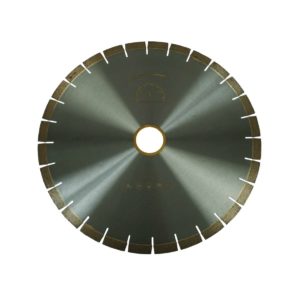

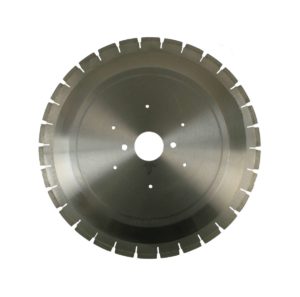

To make a diamond blade, a diamond/metal composite is attached to the outside edge of a metal blade. The metal-diamond composite wears away at the cutting edge over time, exposing new, razor-sharp diamonds. Standard 7-inch saw with diamond blades. A circular saw is a significant investment, but it is well worth it if you cut a lot of concrete because it will outlive and outcut dozens of abrasive-type blades.

There are two types of diamond blades:

Dry-cutting diamond blades

To aid in cooling and waste ejection, dry-cutting diamond blades typically feature a serrated or toothed rim (Photo 1). To get the most out of them, make a sequence of cuts that get progressively deeper. The cloud of fine dust created during dry-cutting brickwork is a major drawback of the process. Do not cut concrete indoors without first enclosing the area with plastic and tape. All vents and openings should be sealed as well.

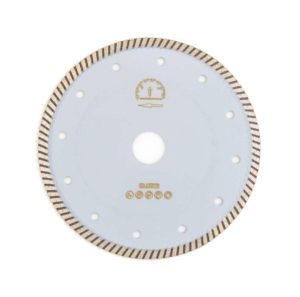

Wet-cutting

Diamond blades designed for wet cutting can either have teeth or a smooth, continuous edge. The water serves to both cool and lubricates the blade, and it also helps to keep the dust to a minimum. These saws are the fastest and cleanest, but they need a special type of water distribution and handling system. In a pinch, you can have a helper carefully guide a thin trickle of water in front of your saw while it cuts, while you put your saw into a GFCI-protected extension chord.

Renting a track-guided, wet-cutting saw and blade is a cost-effective solution for a single large project. A range of hand-held saws and walk-behind saws for cutting or scoring concrete slabs are available at tool rental stores.

To avoid dulling a diamond blade, avoid cutting soft materials. The metal-diamond composite cutting edges must be worn away, which requires a hard substance. Even though it seems counterintuitive, sharpening a blade involves making a few cuts through a tougher substance to expose fresh, diamond-like edges.

Concrete saw cutting dos and don'ts.

For cutting through the hollow concrete block, one must first score the line.

You can use a cold chisel and a hand sledge to cut the concrete, provided that you don't need a precise cut. With the chisel, make three or four parallel scores down the length of the cut. Cutting or scoring the block with a circular saw fitted with a masonry blade is another option.

Chipping away at the excess after cutting through a hollow concrete block.

After a goal is scored, the concrete on the other side of the line must be chipped away with increasingly severe whacks of a hand sledge. You can jump into a block from the top or the bottom.

Using a regular circular saw for cutting concrete, pavers, and other slabs

If you're cutting something somewhat small, use a regular circular saw with a corundum or diamond blade. Slabs are easiest to work with if you first break off the top inch with a saw and then smash the remaining pieces with a hammer. The rough, ragged edge left below the cutting line is ideal for the fresh concrete to adhere to.

Using a gas-powered saw to cut concrete slabs like sidewalks.

Portable and powerful, gas-powered saws are ideal for a variety of jobs.

Modifying the shape of concrete pavers and ceramic tiles.

If you want to cut pavers or tiles with precision and ease, rent a track-guided, wet-cutting masonry saw with a sliding table. A standard 4 x 8-in. board can be sliced in half with the help of a decent saw and the appropriate blade. A cement paver may be laid in about ten seconds.

It's a clean break through the toughest of concrete.

This 12-in. thick piece of wood is no match for the wet-cutting, track-guided saw. Concrete or poured walls. A professional can cut this egress window opening for you in around three to four hours for an hourly rate of $100 or more.

It's not a good idea to shove a blade through an opening. Allow the saw's blade and weight to do the work.

To avoid the blade from overheating when dry-cutting, it is recommended to back off and let it run free every 30 to 45 seconds.

A dry-cutting blade doesn't require water to function, whereas a wet-cutting blade always needs to be used in conjunction with water.

Wear protective eyewear, ear plugs, and a face mask whenever you cut concrete, but especially while you're doing so dry.

Wall Sawing

Wall sawing is the process of making door and window apertures in concrete walls, typically up to 12 inches thick but in some circumstances up to 24 inches thick. A saw mounted on a track on the wall can be used for this purpose. In this method, a diamond blade as large as 30 inches in diameter is used to make a single pass through concrete as thick as 12 inches. This is the most difficult part of running a company and requires professional expertise. Cutting gaps in concrete foundations is one type of wall sawing, but the term can also refer to removing all or part of a foundation and even sawing through retaining walls made of concrete. Expertise and training are required for this form of concrete cutting, making the service quite pricey. This is because the apertures must be cut absolutely smooth, plumb, and level, with minimal dust and mess.

When adding on to a house that already has a basement or cellar, the homeowner will typically have to dig through the existing concrete foundation to create a doorway or passageway connecting the two levels. Having this done before construction begins rather than later is preferable from comfort and financial standpoint.

Core Drilling

Concrete walls and floors can be core drilled to produce perfectly round holes. The hole sizes range from 1" to 12" in diameter, with the average being 5" for domestic use. Core holes for commercial use can be any diameter up to 60 inches. Core holes are typically drilled for the purpose of venting a heating appliance or a clothes dryer, but they also serve other utility penetration needs. While it's not advised for the average homeowner to attempt core drilling, the tools needed to do so can be rented or purchased from any hardware shop. A professional may unload his equipment, core the hole, and reload his equipment in as little as 10 minutes for a minimum charge of $250, but most organizations require much longer. Still, I know of cases when homeowners rented the necessary equipment, spent an entire weekend trying to core a single hole, and then had to call in a contractor to finish the job. A skilled concrete cutter, like a craftsman in any field, will make his work appear effortless.

Slab sawing

Concrete floors, bridge decks, and roadways can all be cut with a slab saw, also known as a flat saw. Slab saws have a single operator and a diamond blade on walk-behind equipment. Despite its ability to cut up to 33 inches deep, most homeowners will only need to use them to cut 6 inches or less. To access and repair a burst water pipe or sewer line, slab sawing is the ideal method for creating apertures or penetrations in concrete floors. It is necessary to break up the concrete in a cellar or basement when installing a bathroom as part of a renovation project. Using a slab saw to remove an old, broken, or unattractive slab of concrete from a patio, driveway, or sidewalk is a common demolition task. In order to make a small change to their yard, some homeowners may request that only a specific section of their patio or other concrete slab be cut. It's possible that the typical DIYer won't have the patience to devote to a slab saw project. On the other hand, it is possible. For the sake of safety and convenience, it's always best to hire a professional concrete cutter, even if it costs a little more money.

Don't let something simple like concrete get in the way of your big plans. A homeowner's biggest nightmare is dealing with concrete, but fortunately, there are businesses that make quick work of the task.

Why Concrete Cutting Using Diamond Saws are Popular

Diamond saws are frequently used because of their versatility, which includes the ability to cut through reinforced concrete's ubiquitous rebars. Circular blades on tracks allow the machinery to scale concrete walls and cut them to size. A flat pavement or floor can be sliced with saws mounted on carts that can be driven in any direction by the operator.

To bore holes for conduits and pipes, a drill shaped like the core diameter is used for core drilling. Commercial concrete cutting on a large scale is typically done with wire saws, which use wires with tiny diamond segments in place of the circular saws used by traditional concrete cutters. These are delicate and should only be handled by experts in the field.